Company Details

Company Details

![]() March 01, 2022

March 01, 2022

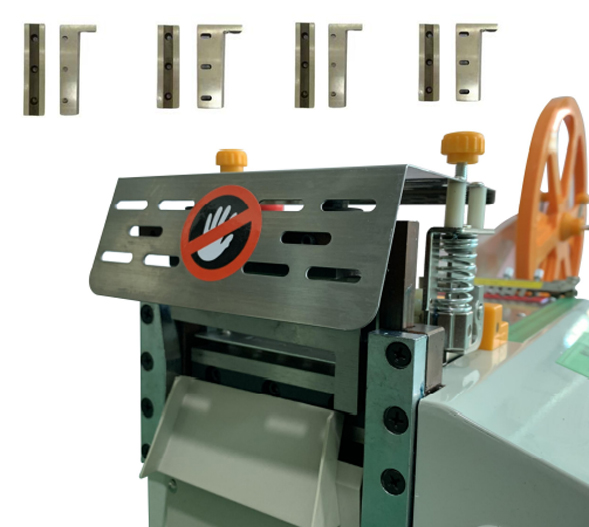

Effect of use and main factors affecting the life of the cutter blade

First, the material of the knife. The monolithic cutting tool is inlaid with a tool made of a blade and a body at a high temperature. The chromium-tungsten-manganese steel blade has a high hardness and a low carbon steel body. Durability of the tool steel blade hardness is proportional to the quality of the blade, the knife blade hardness up to 60 quenched HR55.

Second, the cutter sharpens the quality of the knife. The higher the quality of the brothers, the longer the tool life and the better quality of the crop.

Third, the shape and angle of sharpening. Single-sided cutters generally use a single sharpening tool with a sharpening angle of 19° to 23°. To sharpen such a shape, the pressure of the inclined surface tool during the cutting process is cut away from the part of the paper stack. The paper base in the section is rubbed, and the bevel of the blade is quickly worn. The cutting edge of the double-sided cutter has obvious advantages, which helps to reduce the load on the machine and increase the sharpness of the crop's accuracy. Therefore, in the case of tool materials, the angle of sharpening should be as small as possible, taking into account the crop's shear resistance.

Fourth, different crop materials. The edge of the reamer blunts the speed of the cutting and cutting of the wear-resistant material during the cutting process. When cutting the paper, the speed at which the blades become blunt and the amount of soft, hard and ash content of the paper texture. The handle during the trimming operation is hard, and the greater the ash content of the paper, the faster the blade becomes dull.

Therefore, the use of various high-end Automatic Paper Cutting Machine, CNC paper cutting machine, program-controlled paper cutter knife, pay attention to skills, thereby improving the efficiency and service life of the paper cutter blade.

Flying Man brand cutting machines used imported white steel, with high-strength and sharp blade, it's very durable. With good quality, the warranty can be extended to two years.

Welcome to visit our website:

www.flyingmancuttingmachine.com

Or contact with Jenny Gu:

Email: jennygu@flyingman.cc

Tel/WeChat/WhatsApp: 0086 13913685958

The above is the Effect of use and main factors affecting the life of the cutter blade we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry